A Biased View of Inventory Management

Wiki Article

The Best Guide To Inventory Management

Table of ContentsTop Guidelines Of Inventory ManagementThe Greatest Guide To Inventory ManagementThe Best Strategy To Use For Inventory ManagementEverything about Inventory Management

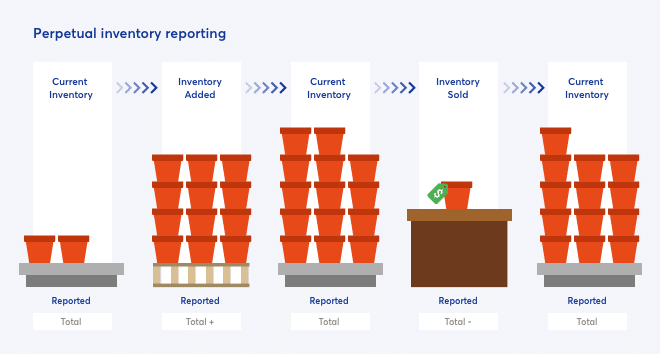

There are two main techniques of tracking stock: periodic and also perpetual. The major difference in between these is exactly how usually information is updated. Regardless of just how usually you track stock, you may wish to make use of among the adhering to stock administration strategies: ABC Analysis, ABC (Always Better Control) Evaluation is stock monitoring that divides numerous things into three categories based upon rates as well as is divided right into groups A, B, or C.EOQ Model, Economic Order Quantity is a strategy used for planning as well as purchasing an order amount. It involves making a decision regarding the amount of stock that must be put in stock at any kind of given time.

FSN Method, This method of inventory control refers to the process of keeping an eye on all the items of inventory that are not used often or are not needed at all times. They are after that classified right into 3 various groups: fast-moving supply, slow-moving inventory, and non-moving inventory. JIT Method, In the nick of time stock control is a procedure used by producers to regulate their stock degrees.

The Greatest Guide To Inventory Management

VED Evaluation, VED is a technique utilized by companies to regulate their supply. It generally relates to the administration of crucial as well as desirable spare parts. The high degree of supply that is needed for production generally warrants the reduced stock for those components. Among the most important factors that a company need to consider is the accuracy of the information presented in its stock data sources.Wrike's product launch automation aids speed up item launches with a streamlined strategy.

Stock monitoring tries to effectively streamline stocks to stay clear of both gluts as well as shortages. Four significant inventory administration approaches include just-in-time administration (JIT), products requirement preparation (MRP), financial order quantity (EOQ), as well as days sales of supply (DSI). There are advantages and disadvantages per of the techniques, reviewed below. A firm's inventory is just one of its most useful assets.

A shortage of stock when and also where it's required can be extremely harmful (Inventory Management). At the exact same time, stock can hop over to here be considered a responsibility (otherwise in an accountancy feeling). A huge supply lugs the threat of putridity, burglary, damages, or changes popular. Supply has to be guaranteed, and also if it is not marketed in time it might need to be gotten rid of click to read more at clearance pricesor just ruined.

Recognizing when to replenish stock, what amounts to purchase or produce, what rate to payas well as when to offer as well as at what pricecan conveniently ended up being complex decisions. Small companies will typically keep track of stock manually and identify the reorder points as well as amounts making use of spread sheet (Excel) solutions. Bigger services will make use of specific enterprise source preparation (ERP) software.

Facts About Inventory Management Uncovered

Suitable inventory administration techniques differ depending on the market. An oil depot has the ability to keep huge amounts of stock for extensive periods of time, permitting it to wait for need to get. While storing oil is pricey and riskya fire in the U.K. in 2005 brought about millions of extra pounds in damages and finesthere is no risk that the stock will spoil or head out of design.For firms with complicated supply chains and also producing procedures, stabilizing the threats of inventory gluts as well as lacks is particularly hard. To attain these balances, firms have developed several methods for inventory administration, including just-in-time (JIT) as well as materials demand planning (MRP). Some business, such as economic solutions firms, do not have physical stock and also so needs to count on solution procedure administration.

Stock has to be literally counted or determined prior to it can be placed on a click over here now balance sheet. Finished products are finished products conveniently available for sale to a firm's clients. Depending on the type of service or product being analyzed, a firm will use different stock administration approaches.

Report this wiki page